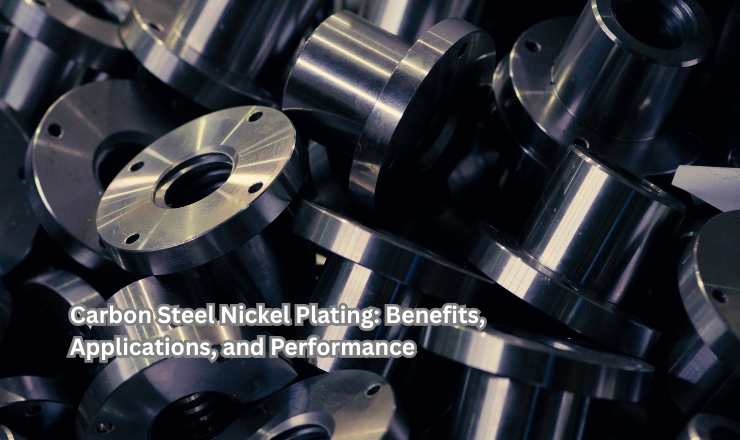

Carbon steel is known for its strength, flexibility, and cost efficiency, which makes it a popular choice in many industries. However, its biggest drawback is its tendency to rust and wear when exposed to moisture, chemicals, or repeated use.

Nickel plating helps overcome these challenges by adding a protective and durable surface layer. Today, many manufacturers rely on advanced metal finishing services to improve the lifespan and performance of carbon steel components.

Getting a Grip on Nickel Plating for Carbon Steel

Nickel plating is an approach that adds a nickel coating of a very thin layer, like chrome, over carbon steel. The layer is like a barrier that acts to protect the steel from many things, like rust, wear and tear, and being eaten by chemicals.

There are usually two ways of doing this process:

- Electro nickel plating, where electrical current is used for the process to control the thickness

- Electroless nickel plating, where a chemical reaction is used for the process to control the uniformity of the coating

What decides the method to be used is the shape of the part, the performance needs, and the standards of the industry.

Nickel-Plated Carbon Steel’s Main Benefits

Nickel plating not only protects metal and adds a decorative value, but also provides a great amount of production and profit advantages:

- Corrosion Protection at Its Best

Carbon steel uncoated can develop rust in no time in humid conditions. Nickel coatings can give a boost of around 85-90% to the resistance of the steel to corrosion, even in the most unfavorable conditions.

- Resistanceto Wear and Abrasion Is Higher

Nickel surfaces have a greater hardness and are more polished than the steel surface has not received any treatment.

For that reason, the life span of the component can be increased up to 2 times or sometimes even more in applications dealing with movement or bearing loads.

- Better Quality of Surface Finish

Nickel gives a bright and very clean, and smooth look to the surface. It is a factor for parts that are going to be used in an assembly where the professionals need to look very standard or aligned with other components or parts.

- Less Expenditure on Maintenance

The maintenance and replacement costs of up to 30–40% are reported by industries using nickel-plated parts. It is due to enhanced durability and reliability, leading to a reduction in maintenance and replacement costs.

- Resistance to Harsh Chemicals and Heat

Nickel coatings can resist oils, fuels, and even mild acids. In addition, they can withstand temperatures up to 400°C without losing their properties, which means they are suitable for use in very harsh environments.

Where Carbon Steel Nickel Plating Is Used

Nickel-plated carbon steel is found in a wide range of industries due to its balanced performance.

- Automotive Sector

- Engine parts, fasteners, brackets

- Better resistance to heat, friction, and vibration

- Industrial Equipment

- Shafts, gears, and machine tools

- Reduced friction and improved load handling

- Electrical and Electronics

- Connectors, terminals, and housings

- Improved conductivity and surface protection

- Aerospace and Precision Engineering

- Components requiring uniform thickness

- Reliable performance under stress and temperature changes

- Construction and Hardware

- Nuts, bolts, and fittings

- Longer outdoor service life

Performance Benefits in Practical Use

Nickel-plated carbon steel delivers measurable performance improvements:

- Surface hardness up to 700 HV, depending on coating type

- Friction reduction by 25–35%

- Consistent thickness for tight tolerances and smooth assembly

These advantages help maintain accuracy, efficiency, and safety in both light-duty and heavy-duty applications.

Conclusion

Nickel plating significantly enhances carbon steel by improving corrosion resistance, wear strength, and overall performance. It helps industries reduce downtime, extend component life, and lower long-term costs.

When professionally applied, carbon steel nickel plating delivers consistent and reliable results across demanding applications.

For expert finishing solutions and dependable quality, Peregrine Metal Finishing provides industry-focused expertise you can rely on.

The Ultimate Guide to Custom Kraft Paper for Businesses

In today’s competitive marketplace, businesses are constantly searching for innovative way…